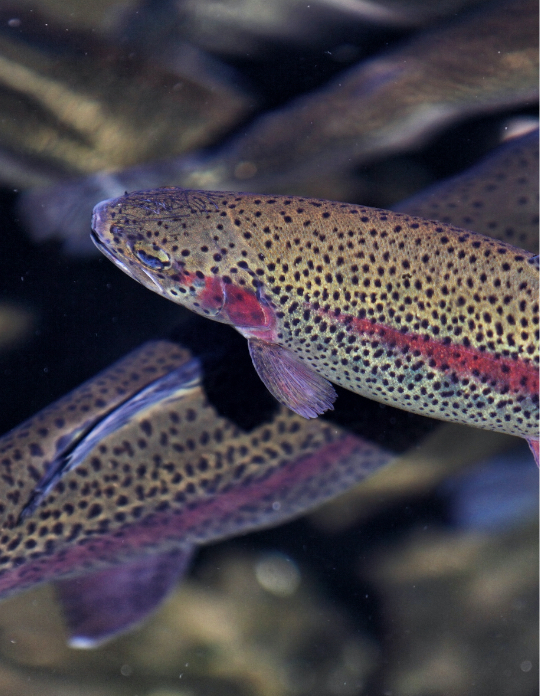

AQUAFLOR® helping you keep fish healthy and aquaculture profitable.

You can count on AQUAFLOR for the control of mortality due to specific bacterial infections in catfish, freshwater-reared warmwater fish, freshwater-reared finfish and freshwater-reared salmonids.

Keep fish strong during an outbreak.

AQUAFLOR is indicated for use in all freshwater-reared finfish.

Where to Buy AQUAFLOR

CAUTION: Federal law restricts medicated feed containing this veterinary feed directive (VFD) drug to use by or on the order of a licensed veterinarian.